PSI . Pounds per square inch. A way to measure just how much air is in your tire, right? If the gauge in your pump is accurate you should have a fairly good idea how much air is in your tires. Does it matter? Do we need to get really specific about how much air is in our tires?

In a word, yes. Air pressure has become a topic among cyclists that feeds heated debates and it’s a somewhat personal conclusion that one arrives at after some testing.

It can depend on quite a few factors. The riders weight, the type and model of tire used, the cycling discipline you plan to be doing.

For instance, someone racing cyclocross may be tempting fate with very low tire pressures in hopes of any kind of marginal gains they may receive with greater traction in mud, sand or grass.

A MTB rider may also be hoping to gain the highest level of performance with a very specific psi that maximises the interface between his tire and the terrain he’s traversing.

A triathlete may also be squeezing every bit of performance out of an ultra light set up that’s designed to shave a second or two off of his last fastest tme.

As you can quickly see, there’s a huge variance in how much air may end up in ones tires depending on the cycling discipline, the tire choice, and of course the riders physique.

A heavier rider will need more air to support his weight and there’s no way around that. It’s immaterial what type of event or bike he’s riding. Air equals support.

If there’s insufficient air in your tires you run the risk of bottoming out on your rim and very likely permanently damaging it, requiring a new rim. No carbon rim is made to sustain that kind of assault. You will very likely crack/damage your rim. So cyclocross riders, gravel riders and MTB riders keep this in mind when determining how low you choose to go with air pressure. It could be a costly error in judgement.

On the other end of the spectrum is very high pressure. Some time trialists may like the feel of a 100 psi tire. There’s nothing wrong with that, but make sure you have not exceeded the recommended tire pressure that you’ll find stamped on the side of your tire. Also keep in mind the potential expansion and increase of air pressure that can happen on a hot sunny day.

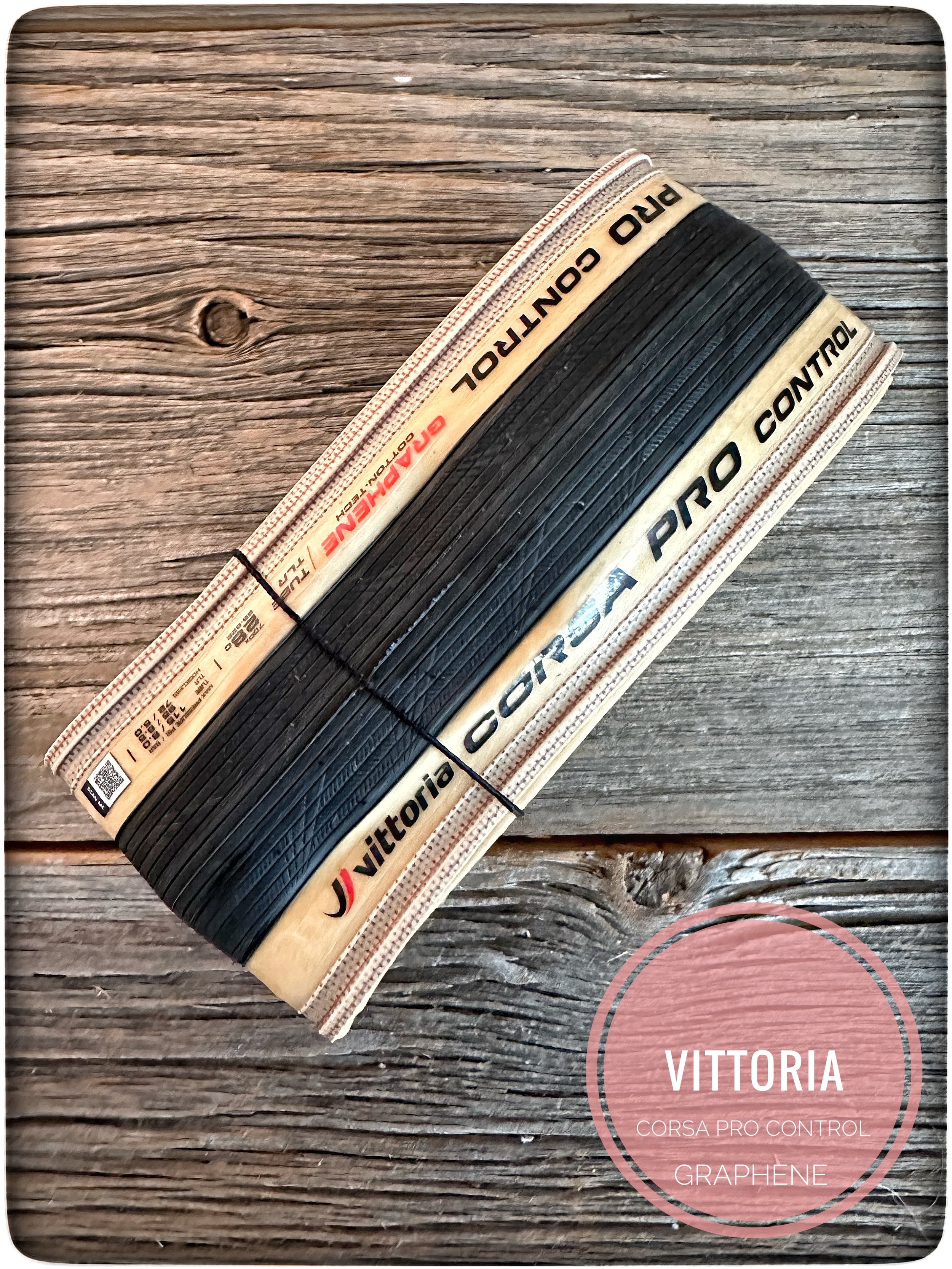

The way a tire is made and the materials used will dictate the “feel” of that tire on the road. For instance, a tire with a 350 tpi cotton side wall is likely going to require a higher pressure to give the tire a nice shape and a secure feel on the road. That’s the result of a very malleable and comfortable cotton side wall that doesn’t offer the same support as a more robust material like a kevlar or other similar materials.

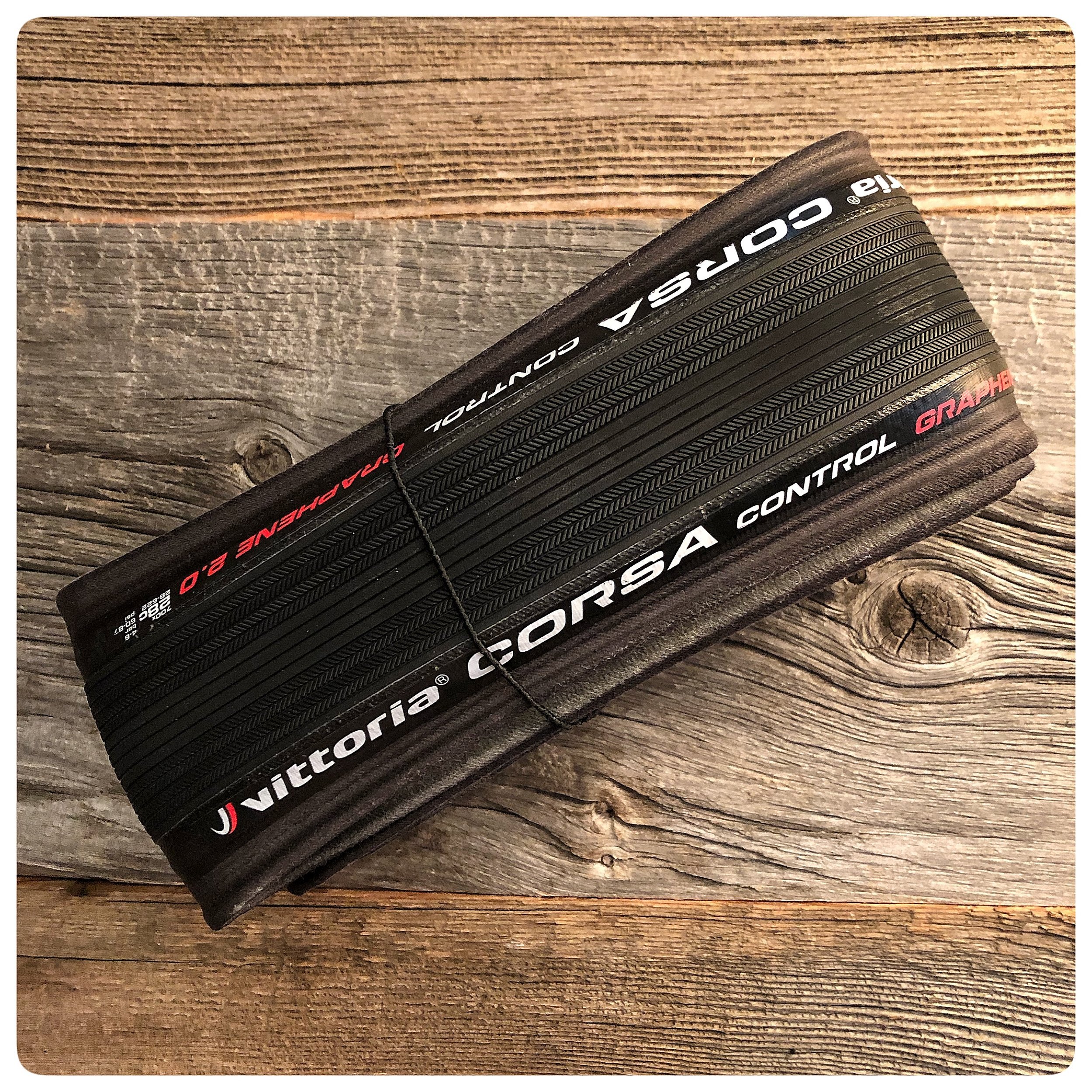

On my road wheels I have fallen in love with the Vittoria Corsa Control 2.0 Graphene tires. They have that 350 tpi cotton side wall that I mentioned. I run them at 100psi and absolutely love the feel that it provides. I wouldn’t even consider running them at a lower pressure. As I said before, this decision is a personal one. It’s what works for me, not necessarily anyone else.

So, you’ll quickly come to realise that your psi decision will require some experimentation to dial it in perfectly. One man’s meat is another man’s poison as they say.

Just be careful not to drink the Koolaid of very low psi. Make absolutely certain that your psi choice doesn’t put your rims at risk of damage.

Eventually you’ll find an air pressure that just feels right. It’s much like your choice of saddle. The saddle that is perfect for my derriere may not be suitable for yours.

Buy yourself a good quality air pressure gauge if you feel the one built into your pump may be off.

Decide on a tire that ticks all the boxes for you. Don’t worry about what so and so is riding. Please yourself. Get to really know the attributes of that tire and what air pressure brings out it’s best qualities. Experiment.

It may take some trial and error but you’ll very likely end up with a specific front and rear tire air pressure that works best for you and your riding style. Keep a journal on how this affects the wear and lifespan of your tires.

Above all, enjoy the ride…