Precision Engineered Wheels

Over the years, my overall approach to wheel building has gradually evolved through subtle but positive refinements and the inclusion of new sophisticated tools. Some of these tools were actually designed by Cognoscenti Cycles, or in cooperation with professional tool designers. Our spoke tension meter is one of those special tools.

I am a perfectionist by nature and realised early on that the perfect wheel required many very specific steps, without any compromises. Part of the mastery of this discipline involves working patiently and carefully checking every last step. Good things take time. The perfect wheel begins with the ideal component selection for it's intended use. It's important to match up the right hubs with the right rims and the correct gauge and type of spokes to complete the build. I like to go over this with my customers in detail to make sure that these choices best suit their needs. The next step is to choose a lacing pattern for those wheels. I am more of a traditionalist in this area, and I like to use what I know will deliver a strong and reliable wheel with a great ride quality. After the lacing pattern has been decided upon I start with some calculations on the perfect spoke length and the type of spoke nipple required. The correct spoke length is critical and must be within a millimetre to satisfy me. I can achieve this level of accuracy with our Morizumi spoke threading and cutting tool. This tool was designed in Japan and is now made in the USA to incredibly high tolerances. Its the gold standard.

After lacing the wheel with properly lubricated nipples, I start with a dead even working tension. This enables me to begin bringing the rim to near perfect roundness and lateral trueness, all happening at a lower overall tension. Very gradually I begin to increase overall spoke tension, in a very measured way so that I can assess how the rim is responding to each additional increase in tension. This is probably the most critical stage, and only years of experience will tell you when you've reached that sweet spot of ideal overall tension. Each and every rim on the market will respond differently according to their design, their weight, and the material that they are made of. This brings us to the last few critical steps: One must confirm that the rim is perfectly centred over the axel ends. This is done with a dishing tool. This procedure ensures that your frame and wheels will be in alignment and ride perfectly straight. The last step is a careful stress relieving of the wheel to simulate riding it. This helps in settling the spokes so that your wheel will remain true on the road. It will also confirm that your tension was even during the truing process. In a properly built wheel, stress relieving should not cause it to go dramatically out of true. At this stage of the build I will use my custom made Cognoscenti Cycles spoke tension meter to help analyze overall spoke tension.

This aids in comparing the individual spoke tensions to verify that they are within an acceptable tolerance. From there, one last final check to make sure the wheel is round, true, at an ideal finished tension, adequately stress relieved and perfectly dished. Lastly I treat it to a degreasing with some organic orange solution to make the wheel squeaky clean and free of any grease or oil that were used on the nipples. Its now ready for pick up / shipping!

Carbon Wheel Specialists

Building with carbon fibre rims requires extensive experience. There is a huge array of makes and models and all of them require specific knowledge, specially designed tools and the correct methodology. Cognoscenti Cycles has that experience and even has helped design some of the tools that are needed for working with light weight carbon rims. We have also been asked to do testing for some well known carbon rim manufacturers, so we are intimately acquainted with this materials’ idiosyncrasies . Carbon is an incredible material with enormous potential in bicycle rims but it demands a very specific approach to produce best quality results.

Each carbon rim design may have unique attributes that need to be understood by the builder. There are several different types of carbon fibre weaves and each one has its own strengths and sometimes limitations. Every carbon rim will require a specific spoke tension profile that we pay very close attention to.

There is also the subject of how that carbon wheel will be used. Will it be a gravel wheel, a road wheel, a track wheel, a time trial wheel, a MTB wheel? Each of those cycling disciplines will require a unique approach to the build.

Only extensive experience in all of these different cycling disciplines will result in great wheels. We also seek out feedback from cyclists we have built wheels for who are participating in the worlds most demanding events. This helps to further refine the process of achieving the perfect carbon wheel.

If you have chosen carbon fibre for your new rims you are in very good hands. Trust us to achieve the absolute best results.

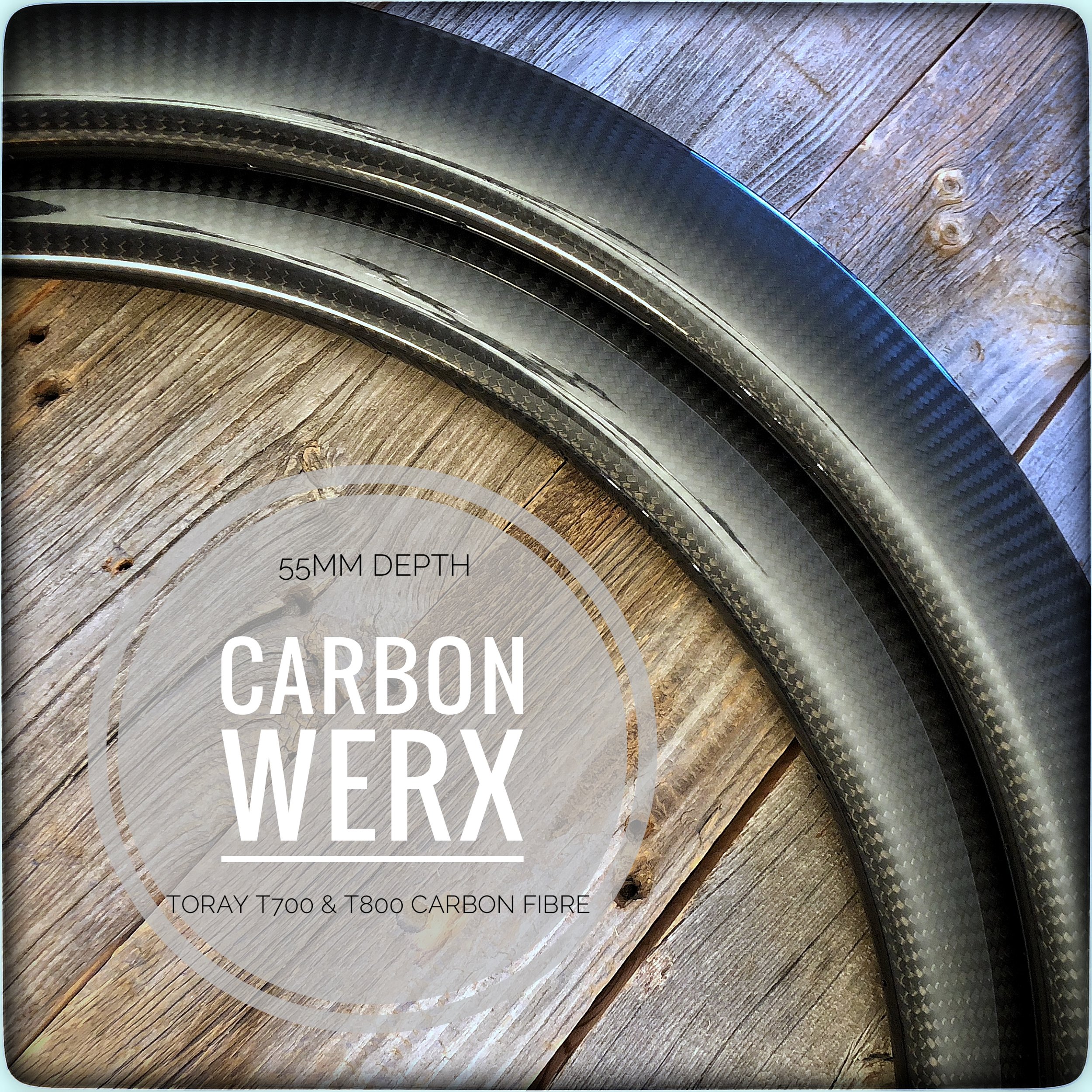

Carbon Werx

Carbon Werx is our own line of ultra high quality carbon rims. For several years I worked to develop a unique line of carbon rims that ticked all the boxes, and that was no easy task! Our rims are all made from aerospace grade Toray T700 and T800 carbon fibre, the absolute best quality and most desirable material for a carbon rim available today. They are also made to tolerances rarely seen in the carbon rim world. Each rim ships with a report card detailing both the radial and lateral deflection too within 2 decimal points and the weight too within a single gram. Accuracy that is simply not seen among our competition.

We can also boast about an impeccable exterior and interior finish. Our clients are treated to several options for both the exterior visible weave and the exterior finish in either a matte/satin or a gloss finish.

We currently have a growing number of cutting edge models for road, MTB, gravel and triathletes. Get in touch if you’d like more specific information or take a look at my blog that has several articles on various Carbon Werx models.