"Born in the Black Forest, built to enjoy nature". You'll find this quote on the Tune website and it sums up their philosophy perfectly! In the small town of Buggingen Germany lies the Tune factory. So what are these guys up to that's so special? Well, it's obvious that they have a near fanatical commitment to building bomb proof and forward thinking components that will endure under the serious demands of off road riding.

Though Tune is devoted to many different cycling products I'd like to concentrate on their wheel related ones, things like their amazing hubs and associated parts.

With over 20 different hub models to choose from I think Tune has your back! I won't attempt to tackle each and every one as that would take quite a lot of time, but lets just say that a trip to their website will be a must do if you want to get hip to every last hub on offer.

I'd like to talk about a few hubs that I think should be on your radar. First off is the "King", a MTB hub that can be configured for QR, or 12/15mm thru axle. This hub is CNC milled from a solid billet of 7075 alloy for a tough as nails shell. The uber stiff 17mm axle accompanies very high quality double sealed bearings that keep the bad stuff out while on the trail. Comes with a standard 6 bolt interface for disc brakes.

The King has not left the building! Tipping the scales at a svelte 115 grams and coming in either 24, 28 or 32 hole spoke counts. Made from best quality 7075 alloy. Available in Tunes 8 different bright anodised colours. Also available in a boost model.

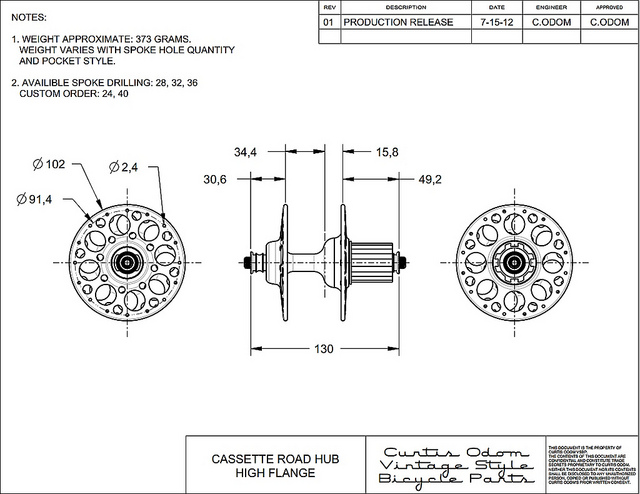

The next hub I'd like to look at is the Mag 170. It also sports a robust 17mm axle mating up with Tune's specially made sealed bearings. This road hub is available in either 130mm or a 135mm rear axle length, making it ideal for the roadie, the cyclocross man, or just about anyone running calliper brakes!

The MAG 170, at a mere 178 grams of Tune goodness! Spoke counts of 16 holes all the way up to 36! In house made sealed bearings and 8 colours to ponder.

A sneak peek inside the Tune Mag 170 rear hub. A 7075 alloy hub shell enshrouding their proprietary sealed bearings.

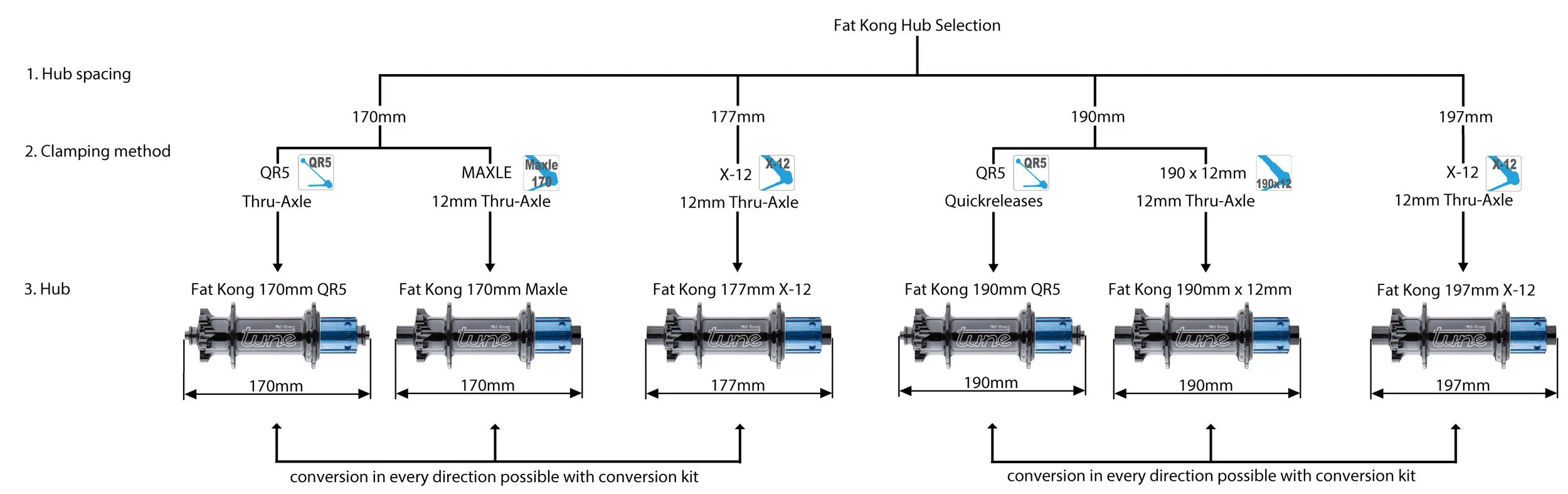

With the growing popularity of Fat Bikes I thought we'd examine Tune's Fat Kong. This hub comes in a few different versions. There is a QR model that is for 170mm/ 190mm. There is also a 12mm thru axle version for 177mm/190mm. Those should cover all the bases. At 240 grams this alloy hub should be ideal for your new Fat machine. It's available in a 32 hole count only and it boasts a symmetric flange design enabling a very strong build, necessary for the type of workout that most Fat bikes will throw at it. In the freehub they employed titanium teeth and pawls to drive this hub. A very good plan in my opinion. It's also equipped with Tune's in house top quality sealed bearings for almost maintenance free riding.

Tune's Fat Kong. Where wide is the new orange!

Build an ultra strong rear wheel with symmetrical flange spacing.

A detailed graphic of all the various Fat Kong options.

8 colour options are available for all of the different hubs that Tune makes.

If Tune looks like an interesting hub option for your next set of wheels I'd invite you to take some time and explore their website. There's a lot to look at! If you need help in picking out the best hub please contact me. I'd be happy to help in choosing a perfect Tune solution!