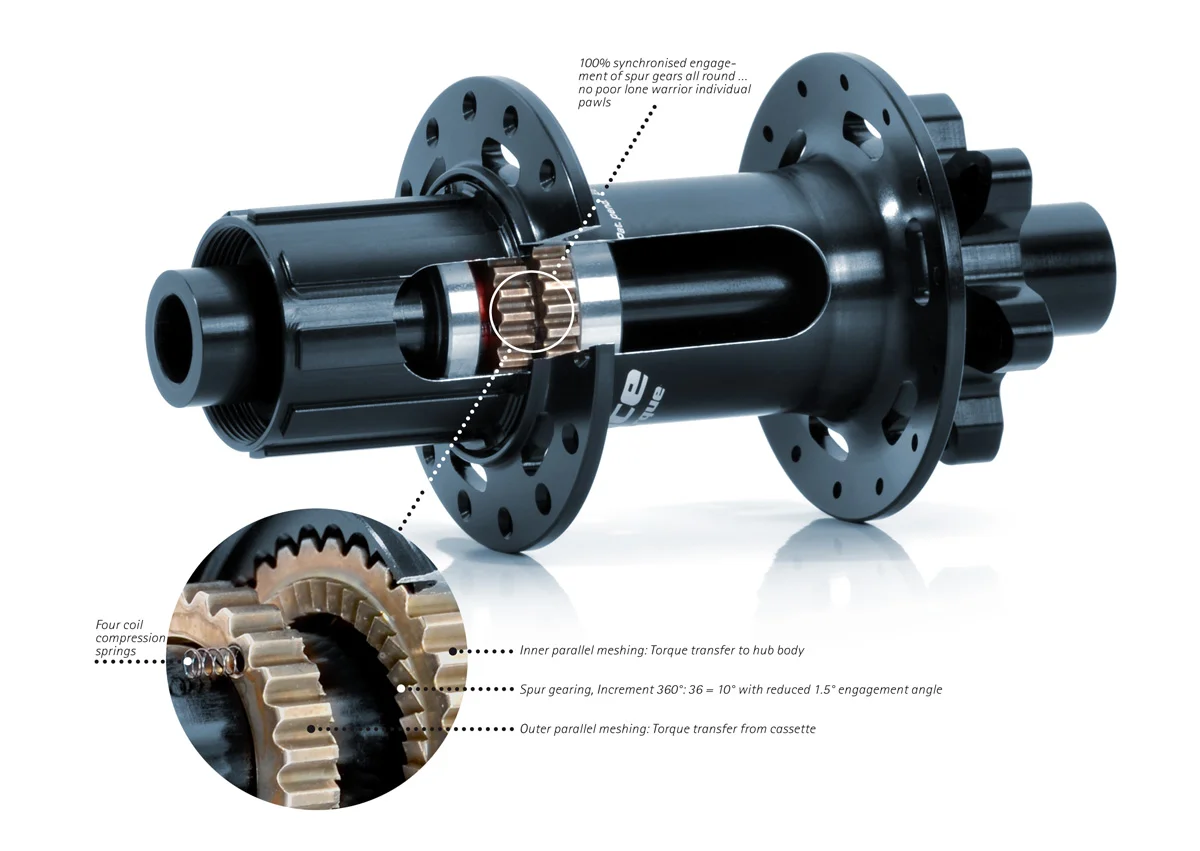

Syntace hubs are the end product of solid German engineering. Right off the bat I should mention that Syntace believes enough in their products that they are backed by a 10 year warranty to repair or replace at their discretion. How many other manufacturers are offering such a warranty? Not too many! So, what makes them so confident in their work? Lets take a look at the insides of a Synatce HiTorque MX rear hub to see how they are unique. First off, the hub shell is made from aeronautic certified high strength 7075 aluminium. The freehub transfers energy via a spur gear design which allows all the teeth to be engaged at the same time. This method means that no individual teeth are ever overloaded. The simultaneous engagement of their high strength tool steel makes for a bomb proof set up. Since 2011 their team riders have not experienced a single failure! Not bad!

Syntace works from their own mantra of "Strong, Light, Smart" and it certainly appears that these ideals have been realised in their hub designs. The HiTorque MX hub weighs 245 grams with a 32 hole spoke count and a 6 bolt disc brake interface. Its current heavily tested track record bears this out. I hope you are in love with the colour black because at this time it's your only choice.

Their sealed bearings incorporate double seals for protection from the elements and also have some degree of micro adjustability of the lateral bearing play via the end caps ensuring greater longevity of the bearings. The freehub is both Shimano and SRAM 11 speed compatible.

The Syntace HiTorque MX rear hub, also available in 148 x 12 boost model.

The HiTorque front hub topping the scales at 175 grams. Available in 15 x 100 mm or 20 X 100 mm axles.

Syntace has a solution if you desire a quieter hub out on the trails. They supply a "silencer kit". This drops the volume by about 6 db and acts as a lubricant as well. An ideal solution if you would rather listen to mother nature than your rear hub!

In just a few minutes you can instil the silencer kit to tame the sound of your rear hub.

For the roadies out there Syntace has the Hitorque Road hub that sports 24 holes and weighs in at just 191 grams. It's also made from 7075 aluminium. A light weight hub that would be ideal for a nice set of training or road racing wheels.

The Hitorque road hub in basic black. 24 hole count only. 7075 alloy hub shell with their micro adjust bearing set up.

Syntace has gone all out to give us hubs that will go the distance. Any company that freely hands out a 10 year warranty knows they have a fairly indestructible product.

Cognoscenti Cycles is now carrying this bomb proof hub and I'd like to see more of these on the roads and trails here in Ontario. If you need more information don't hesitate to contact me!